Bridge Racker

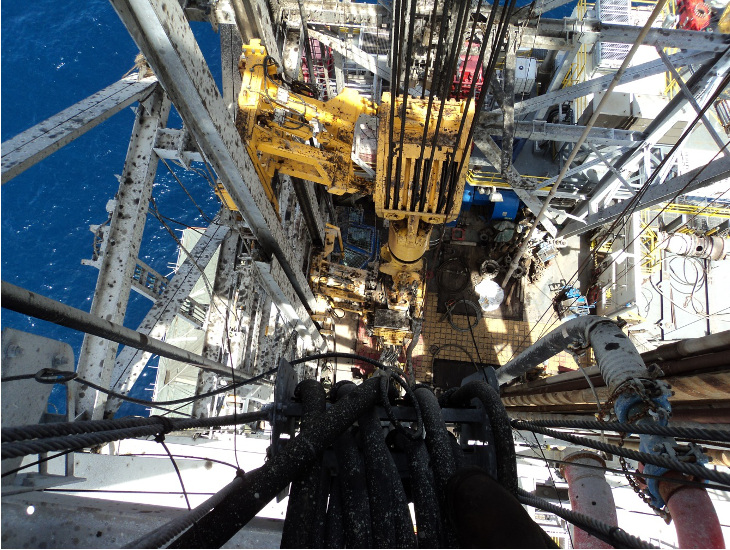

The BRC is a double girder overhead crane type construction running on parallel rails mounted high in the derrick

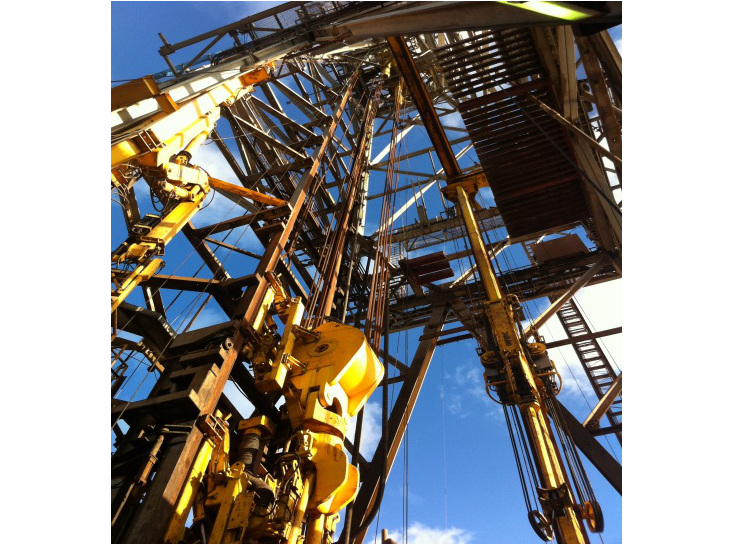

Typical Lower Racking Arm

The Bridge Racker consists of:

- Bridge Racking Crane (BRC) this is mounted in Derrick, above the Fingerboards

- Lower Racking Arm (LRA), also referred to as Z-Arm, this is mounted at Drill floor level in the Setback area

The gripping and lifting capability of the BRC combined with the captured guidance of the LRA enables vertical stands of pipe to be handled and guided safely between Setback to Mousehole to Well centre

EFC combines functions to enable the grip head to access all the stand positions in the fingerboards and lift and transfer each stand. Simultaneously the LRA combines following functions to capture and guide the bottom end of the stand safely into position:

- telescoping

- luffing

- slewing

- latching functions

| FEATURES | BENEFITS |

|---|---|

| Fully Captured Handling of Vertical Stands | Eliminates manual handling |

| Compact Grip Head | Easy access to busy racking area |

| BRC Tubular range | Available up to 20" Casing grip heads |

| LRA Tubular range | Up to 9 3/4" (bespoke on request) |

| Grip head stroke | up to 4,500mm |

| BRC & LRA Control | Synchronised |

| Safety | Anti-Collision option is available |

| Working Loads | up to 10,000 Kgs |

| Slewing | Continuous, 360deg |

| BRC lifting capacity | 5,000kgs (up to 10Te if required) |

| Hydraulic gripping | Simplifies the handling sequence as the stand can be gripped anywhere, not just under the tool joint |

| Controls | Pilot-Hydrualic or Electro-Hydraulic |