Rack Phase Difference (RPD) and Leg Length Monitoring System

The RPD is a tool designed to monitor the Rack Phase Difference (RPD) during jacking operations.

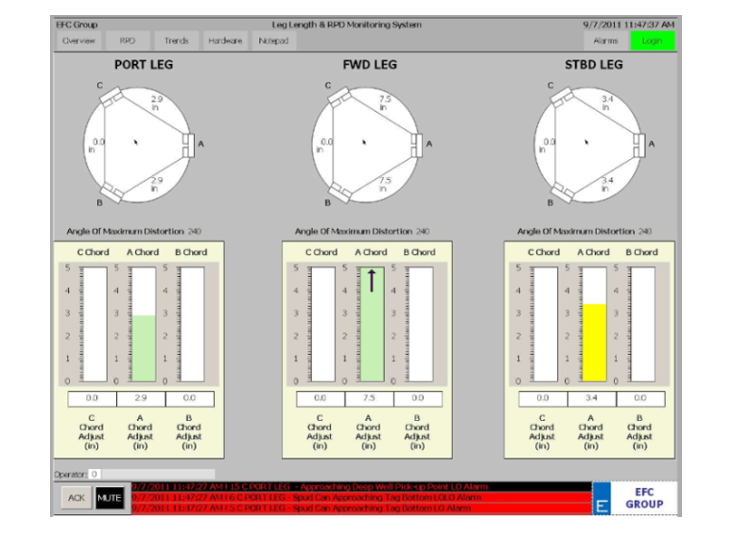

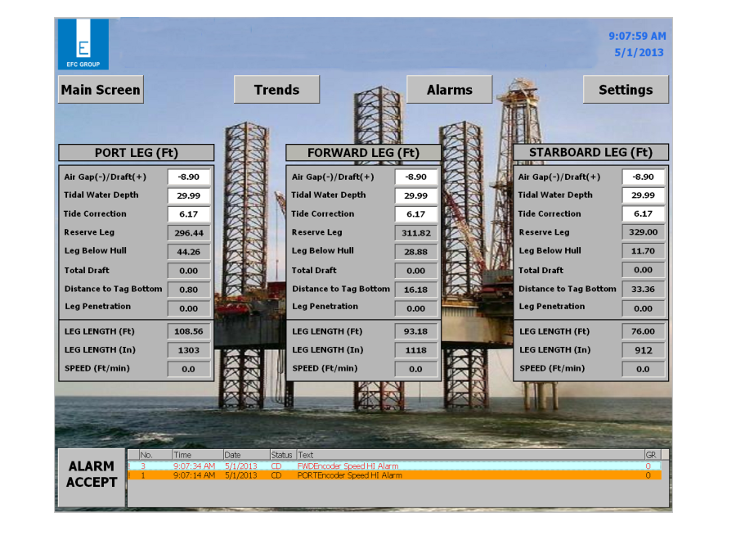

Typical Monitoring User Interfaces

Three chords per leg are monitored in order to manage the RPD phenomenon. The RPD will compare the length between each of the three chords per leg on all three jackup legs and gives the operator an audible and visual warning where one chord has moved lower or higher than the other two beyond acceptable limits.

The system also includes EFC's Leg Length Monitoring System which provides the operator with clear data on the extension of each jack up legs and other critical data during the rig jacking process, historical trending, data logging and an alarm provides visual and audible warning.

| FEATURES | BENEFITS |

|---|---|

| Non-Contact Coupling | Ensures zero mechanical interference or shock from pinion drive |

| Programmable Logic Controller | Allow for future expansion for any further of EFC IMMS System, as well as providing archiving and trend analysis for the operator |

| Event Logging | Allows the operator to enter text into the event report. This allows for the operator to create reports |

| Trend Analysis | A trend screen allows the operator to select and view the historical trends of each individual leg’s chord lengths against time |

| 2-Point Monitory | Corrects for RPD errors caused by lateral leg movement |

| Separate Network | In the event of an encoder or network failure the system will continue to operate but the RPD alarm point will be reduced |

| Remote Indication | Provided locally at each chord by providing the operator information to correct RPD error |